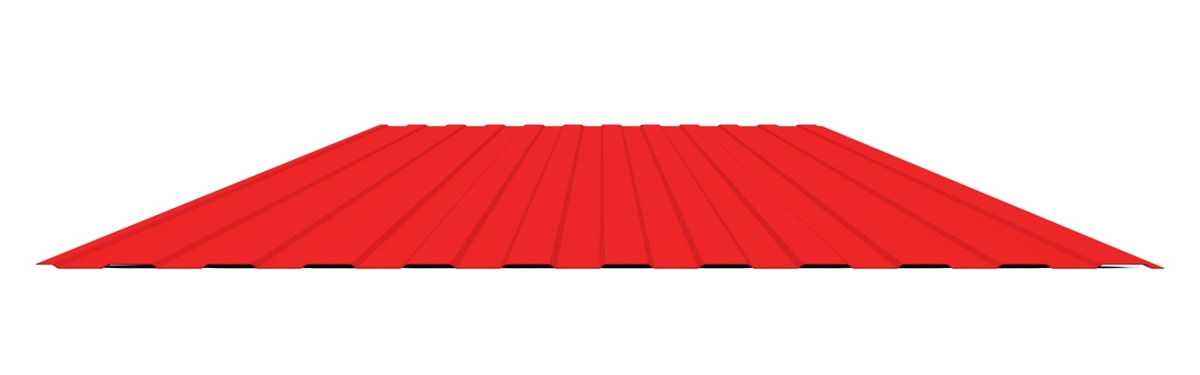

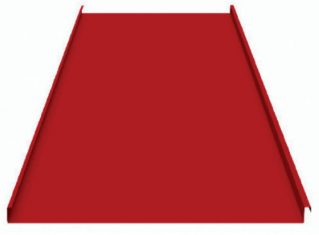

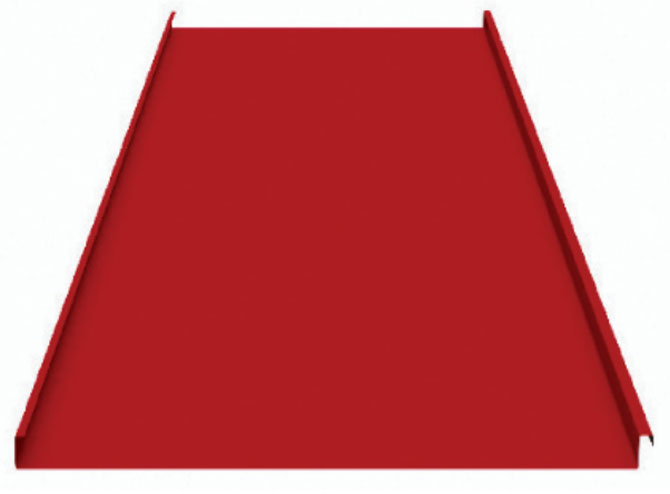

Glossy fold roof with the horizontal riffle is very flexible and it can be used for profiling of all shapes and angles of the roof surfaces. It is connected by the double riffle and safely fixed with the clips. Accepted slope for the flat panels´ is given by the standard – 7°, with the possibility of overrun of this limit up to the permitted 5° – an additional tightening has to be used. This adjusting of the additional tightening is need to be present the critical locations with the assumption of snow accumulation.

Installation:

For fold roofs is surface without any irregularities, which are duplicated by sheet metal and cause the unshapely signs on the final roof.

Basement (lathwork) should satisfy these parameters:

- the woods should be treated chemically

- wood’s humidity must not exceed 30%

- minimum thickness of wooden foundation is 24 mm

- width of laths is within the limit 80 to 140 and they are angular

Anchoring:

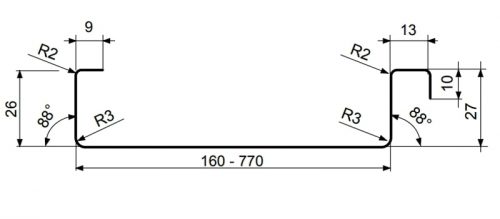

The fold roofs is anchored only by one allowed method – by the clips (compact and movable clips). The clips are made from zinc-coated or stainless steel. The compact clips are possible to make from the same material as the roof. The movable clip is irreplaceable and has to be used at the band’s length longer then 2 m. The clips are input to the open riffle in the regular expansion. Usually is the expansion 400 mm, however this rate can be changed according to local pressure of the roof surface. The clips are mounted by 2 nails (spacing of clips to 600 mm). It must apply that the tensile force of the wind acting on 1m2 has to be lower than the force needed to pull out of the total number of clips placed on the given meter. The compact clips are used in “compact zone”. All other roof surfaces have to be embedded by the movable clips. The compact zone has got a width of 2 m (measured along the chevrons) and the length according to given roof.

Machine equipment and tools:

Metal roof sheet is possible process manually, but simplier by a machine. Details of sheet covering of valleys, gable dormer, passages and other specialized places is necessary to handle by standard plumber process. By processing has to be made allowance for the surface coating of the sheet. It is necessary to avoid using of the sharp metal instruments, which can in large extent damage the protective polyester layer. For various process methods apply various temperature limits. With the temperature decrease the sheet metal tends become brittle. It is possible to prevent an unfavorable behavior by maintenance of the correct operating temperatures.

Machine processing +14 °C

Manual processing +16 °C

The bands in desired length are ready to installation on the roof, where are consequently closed by machine folder. By installation of the riffle the water outflow has to cross this riffle – it can never flow inside. It is prohibited to use combination of other manufacturer’s machines as well as the combination of different types of roof!!!

During riffle closing comes to connection and underlay of cca 5mm metal sheet. That can influenced the folding, while the roofing is firstly griped into the clips and then all riffles are closed at once. At long roof can come into incorrect action of mentioned 5 mm. It is possible to prevent such problem by continuous folding at installation and anchoring of the bands.

Additional tightening of riffles:

If the slope of roof surface falls under 7° an additional tightening is need to be installed. The tightening stuff can be self-adhesive elastic tape, folding oil or neutral plumber sealant. For minimum slope 3,6°- 5° is suggested using of sealant tapes. The disadvantage of the sealant can be its non-constant application or clogging of shaping machine with squeezed-out sealant’s rests. An additional tightening fulfils its task especially in winter season, when on the roof lays a snow-layer. It can come to water capillary action through the double riffle. Unless the roof has got an adequate slope and it is not likely that the snow will remain on the surface. The tightening has got rather safety function and is useful furthest in mountain regions. At the buildings with the roof lap can occur a complication of unconstant snow thawing. The roof’s laps, in contrast to roofing over the building, are not heated from beneath and so the snow mounds are accumulated on the top. These natural obstructions allow the formation of a channel that is filled up with standing water from warmed part of the roof. Unless there is not in such part sufficient tightening, it is possible to predict that the water penetrate into the construction.

In the mountain regions and on the complicated construction there is necessary appraisal and determinate of additional tightening usage. It is most probably, that the tightening has to be used also on considerably steeper slope then 7°. The costs of tightening are negligible in comparison with the damages caused by leaking problems.

DIFLEX FOIL

It is a highly diffuse membrane under a folded metal sheet roofing for shuttering. The drainage layer creates a gap between the folded roofing and the membrane and at the same time, it removes condensation from the covering to the membrane and draws moisture out.

Wind bar for FALC

The so-called gable edging of the folded roofing. It is used to end the roof on the sides after the slope, but also as the upper end strip of counter roofs. Its purpose is to prevent the roofing from blowing. It also prevents rainwater or snow from flowing under the roofing. It is produced in 2m lengths.

When calculating the number of pieces, a 10 cm overlap must be taken into account.

Wind bar for KLIKpanel

The so-called gable edging of KLIKpanel. It is used to end the roof on the sides after the slope, but also as the upper end strip of counter roofs. Its purpose is to prevent the roofing from blowing. It also prevents rainwater or snow from flowing under the roofing. It is produced in 2m lengths.

When calculating the number of pieces, a 10 cm overlap must be taken into account.

Gutter edging for FOLD and KLIKpanel

It is also known as a “starting bar“ because it serves as a starting profile for the strips of folded roofing or “KLIKpanel“. The edging must be installed in one level to ensure simple and parallel installation of the roofing. It is produced in 2m pieces. When calculating the number of pieces, a 10 cm overlap must be taken into account.

Comb Z ventilation bar

Perforated Z-shaped bar, which is placed under the comb and serves to ventilate the roofing. It is produced in 0.5 m lengths for easier installation between standing folds of folded roofing or in a length of 0.46m for KLIKpanel. It is used on both sides of the comb and of the corner.

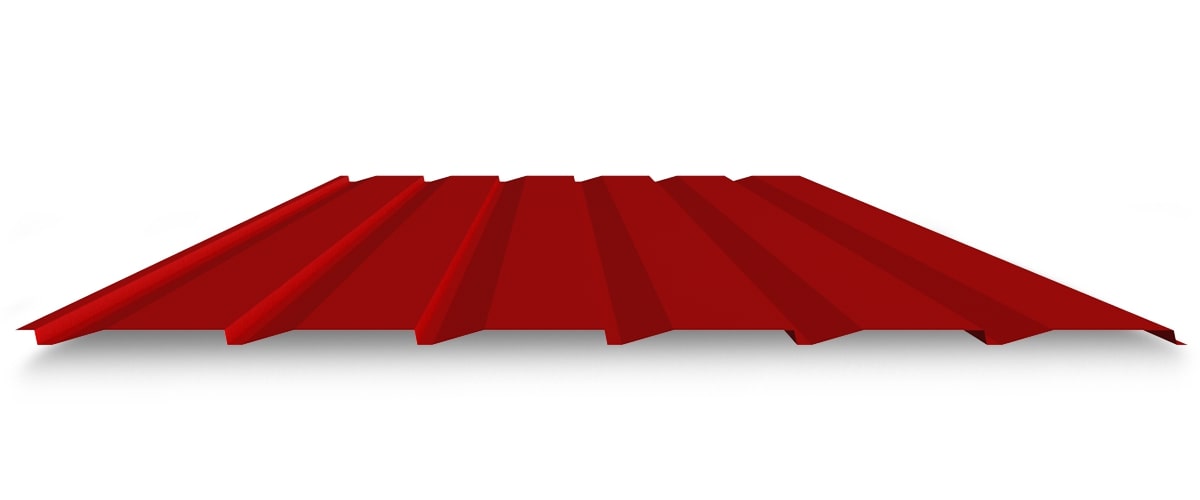

EXPANSION TAPE FOR FOLDED ROOFING

They are used to permanently seal a standing fold at low roof slopes to achieve a waterproof joint. It can also be used in the lintels of trapezoidal sheets to seal the joint at low gradients.

STAINLESS STEEL ATTACHMENTS TO FOLDED ROOFINGS FIXED AND MOVABLE

It is used to fasten folded roofing into a wooden roof structure. Available in two sizes 25mm and 28mm. Fixed 25mm under the classic foil 135 g and movable 28mm on the diflex foil.

Warranty up to 60 years

Warranty up to 60 years  FREE fast delivery

FREE fast delivery  FREE measuring and laying plan

FREE measuring and laying plan  Quality Slovak product

Quality Slovak product