INSTALLATION: Before we begin with lathing and laying of the roofing itself, it must be select the correct roof deck composition. It is important to note to what will serve attic space in the future and according to this knowledge select the right solution. If the attic will be uninhabited (unheated) and not insulated, it is necessary to solve complex roof track. It is good to use quality diffusion films which are fully opened. The space between the covering film and a diffusion is always necessary to sufficiently aerate. In both case – where the film is located on a formwork or on the thermal insulation. This kind of ventilation is achieved by the contra laths (Fig. A, B). which one ventilated gap between the eaves drip and the ridge. The air spaces we protect by the protective vents and the protective ventilation strips which prevent to penetration of insects, birds, leaves to the roof spaces. Ventilation grids can be replaced by a sealing strip, which is more suitable for roofs with low slope or if it is the windward side (it is up to an architect or an engineer).

Fig.A Roof coat with lathwork

Fig.B Roof installation without formwork

Description: 1 – metal roof (ŠKRIDPLECH, GAPA); 2 – screws with sealing mass; 3 – leeward slat (under the roofing), 4 – lath; 5 – ventilation gap; 6 – diffusion foil; 7 – contra lath; 8 – chevron; 9 – gable lath; 10 – insulation; 11 – sealing

Lathing:

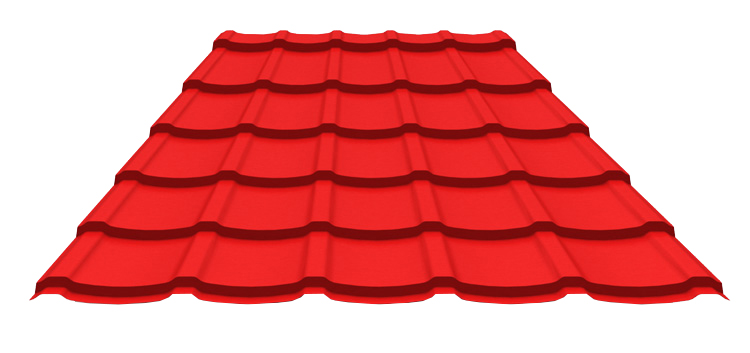

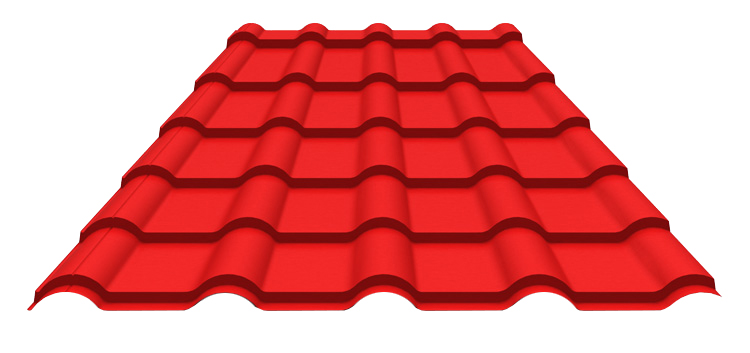

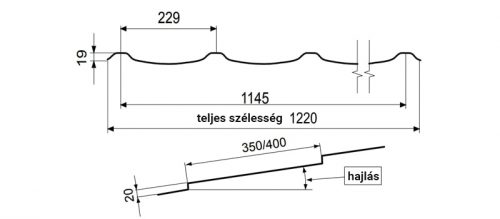

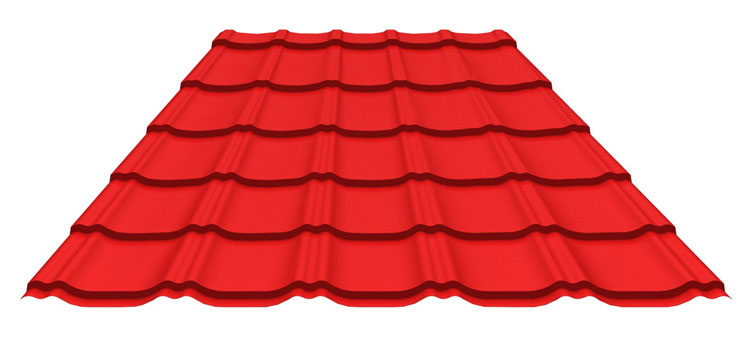

For roofs such as GAPA and ŠKRIDPLECH it is necessary to keep a minimum roof slope – 12 °. Lathing is the most important process before laying of the roof. Correct and precise lathing simplify and speed up installation of roof. It is reasonable check the roof before installation, not only in terms of parameters but also in terms of inhomogeneous structure, which can adversely affect on the installation. Batten gauge is 350 mm. Finishing lath is usually placed about 30-50 mm from the top of the roof. Weight of roof is approximately 5 kg/m2. In case that we not use a gutter rimming, we recommend to drub the lats to reverse, because at this point we anchor the roof behind the overpress. From the reason of the condensation of air humidity we recommend use a insurance hydro foil. In case of the insulated roof is using of this foil necessary. Using of this waterproof foil is necessary to pull up on the gutter rimming. The counter laths are nailed along the chevron and after that it could be used lathing. First of all it has to be installed gutter hooks according to appropriate slope (in the case that they are not installed to the front lath) and a roof window according to the instruction of the producer.

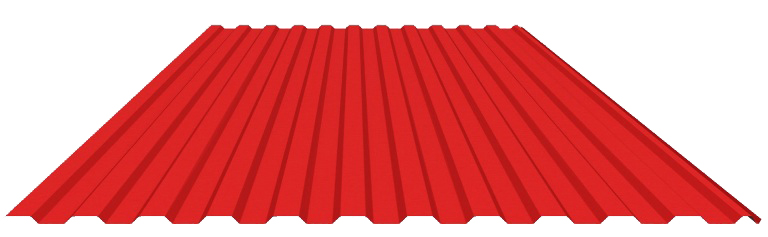

MANIPULATION:

Steel sheet con not be deformed during the installation. Try to manipulate with the sheet upright. As far as we handling with the sheet in a horizontal position, it is necessary to exercise caution, as may occur in the individual profiles of the longitudinal deformation. This danger arises mainly with sheets of size greater than 4 meters. For easier handling we recommend to use the sheets of smaller lengths, especially if is in the building not enough space.

RECOMMENDATION:

When a ladder is present, it is suitable to cover contact zone with the wrapped foam against to scratch. It is possible to walk on the roof, but be careful you have to walk at the bottom of the waves and the point where the roof is supporting by the laths. It is recommended to use shoes with soft sole. In case of a damage is necessary to treat this place by corrective color.

For all of our costumers is worked out an installation plan for free. This plan helps to speed up and simplify the whole installation. The sheets is always important to put on a drip edge according to installation plan. Installation is possible from both sides – right or left. In some cases it is reasonable covering from the left site. The sheets is need to be put under the already installed table. The result should be that a sheet has to fit into the lock and can not move downwards.

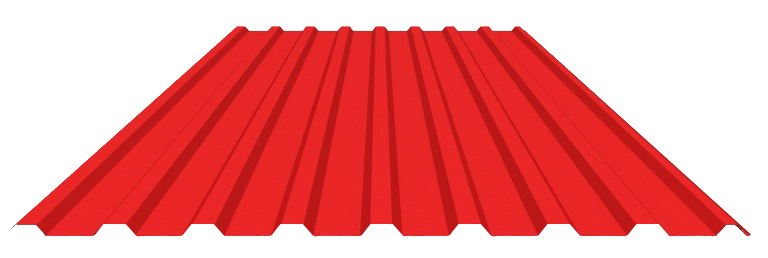

Anchoring of the roof:

Roof is fixed on the structure by self-drilling screws with sealing pad with special rubber EPDM with dimensions of 4.8 x 35 mm. The screws must be tightened by electric screwdriver with stepless power. The screw is securely tightened when EPDM pad “climbs” (come out) from the metal pad. Average consumption of screws is 6-9 pieces per m2. The screw is placed about 2 cm below the overpress into the valley. At the edge of the roof must be anchoring denser – Fig. At the ridge of the roof it has to be anchoring to the bottom of each wave. On the joints sheet – sheet is used self-tapping screws with dimensions of 4.8 x 20 mm. The longitudinal overlap is appropriate to screw covering about 2 cm below the overpress over the top of the wave.

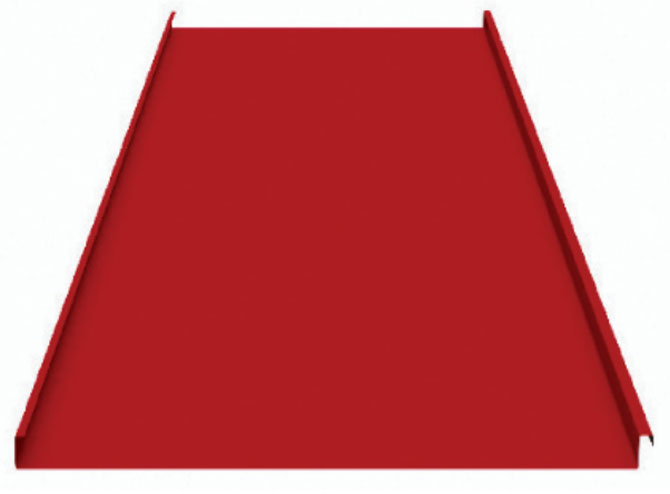

DIFFERENCES IN INSTALLATION OF ROOF AluGAPA

When is aluminum roof installed it is necessary to know another principles than of steel roof.

1) The aluminum covering is not possible to anchor with any of previous accessories. This is particularly the ridge and snow barriers, which are always anchored to the roof laths by screws 4,8x60mm. Lathing at the ridge must be denser for effective anchoring.

In case of snow barriers installation is necessary to anchoring the place where will be the snow barriers install.

2) Connection between sheet – sheet ensure the screws 4,8×60 mm – they have to penetrate to the lathing.

3) Screws to aluminum roofs are made of stainless steel. When the other elements are used, the life of the roof can be shorter.

Screws are calculating by the coefficient:

6 x (4,8×35 mm) per 1 m2 and 3.5 x (4,8x60mm) screws per 1 m2. Screws with the dimension 4,8×35 mm are packed 250p in the box and screws 4,8×60 mm 100p in box.

Roof ventilation:

Very important is the quality of roof ventilation. On the ridge is left gap between covering a width of about 11 cm, which is covered with a universal ventilation band. Roof is then ventilated through the openings between the ridge tile and roof. The ridge tiles are screwed into the roof every other upper wave. After anchoring the roof and ridge tiles we should install other accessories.

Dividing of the roofs:

We are usually divide the roofs by adapter to drill. All cuts must be treat by protective varnish and remove metal shavings, which could start corrode in the future. Never use the tools with grinding wheels because they could cause heating of the cut area which damage the polyester layer. From flying pieces of molten steel – sparks impact on the roof up to several meters in distance from the cutting (and later, after a few months to years) cause the occurrence of characteristic yellow spots, followed by deep corrosion causing rusting metal. In the case of usage machines with the thermal effect we cann not guarantee any warranty!In case of the installation is necessary to remove metal filings from the plate surface with a soft brush!

STORAGE AND MANIPULATION:

The material should be stored into a dry and ventilated warehouse without direct sunlight on the pallets 20 cm from the floor. It must not be stored on each other more than 30 days, because there is a risk of moisture from the air and formation of white corrosion. If the material is stored over 30 days it is neccessary to remove it into individual thin sheets of wood panels and underlay on one side so that it can be drained. The material has not to be rained it has to be protected against the incorporation of the water into the edges of the material. In case of incorporation, each sheet should be deploy and dry.

ATTENTION !!! Sheets stored in an open air depends at the weather (especially of wind). If the time from delivery to installation is more than 30 days, we will not be able to accept claim connected with the quality of the surface.

Warranty up to 60 years

Warranty up to 60 years  FREE fast delivery

FREE fast delivery  FREE measuring and laying plan

FREE measuring and laying plan  Quality Slovak product

Quality Slovak product